Armortex® Fabrics – Approved by A Prominent Work Glove Supplier

Protective Fabrics Meet ANSI Class 9 Cutting Standard With 360° Protection

Improved Textile Technology Creates an Affordable Fabric for Work Gloves

Improved Textile Technology Creates an Affordable Fabric for Work Gloves

ANSI 9 technical fabric provides cut and stab-resistant functionalities.

Based in Taiwan for the last 10 years, Nam Liong has been a fabric manufacturer of Mechanix Wear, providing cut resistant work gloves for skilled laborers or grunt work. Mechanix Wear is an industry leading American workwear and protection gloves supplier with sales across North America and Europe. Their procurement of Nam Liong's high-performance technical fabrics has proven their trust in Nam Liong's patented and registered fabrics, namely Armortex®. The provided effective technical fabric, Armortex®, is a breakthrough to many suppliers/retailers who wish to enhance their product functionality in the competitive market. Nam Liong has been in the textile industry for over 50 years. Their seasoned experience has allowed them to innovate and develop synthetic fabrics that no one can compete with.

Many textile suppliers have been developing textiles in a way that can satisfy customer's needs in the market. Therefore, technical and functional fabrics for various industries were invented. Three years ago, an approach to a highly protective work glove fabric was acquired by the client. It was to create a fabric that conforms to the highest ANSI class with 360-degree protection. In theory, to build a strong and slash resistant fabric needs steel mesh, the thicker it is, the stronger it becomes, and vice versa. It is contradictory to make a fabric that contains all the necessary properties, which is hard and thick for a good cutting score, and smooth and flimsy for work dexterity. The client checked with a few fabric manufacturers, only Nam Liong replied with the likelihood to succeed knowing it's challenging. The client believed that Nam Liong was being realistic and would make the biggest effort to achieve the objective.

Generally, a cut and stab-resistant fabric is a composition of yarns, linings, and steel wire mesh. Strong metal mesh delivers excellent cut resistance; however, its weight can be cumbersome for users. Incorporating yarns and metal wire meshes was another challenge. First off, mesh cannot break during knitting, or the fabric will lose its functionality. Second, how should the yarns align, horizontally and vertically, to enrich the durability and pass ANSI 45-degree cutting and electrical insulation tests? Finally, what is the exact proportion of interlaced yarns and the adhesives? The manufacturing process, such as fabric coating, chemical dyeing, finishing, printing and aftertreatments, they are all important factors that cannot be ignored. Additional functions like adding a coat for slip/abrasion resistance or chemical treatment for water repellency are critical for the level of fabric performance.

High-quality Cut Resistant Fabric is Made Professionally | Armortex® Fabrics

Work glove fabric with refined tungsten wire mesh

To reduce the weight and add work flexibility, Nam Liong decided to use tungsten wire mesh. Purified and refined tungsten wire mesh empowers the durability of fabric, and the lightweight of the mesh allows operators to move freely. Even so, there was no company selling tungsten wire mesh in the textile industry, so finding a supplier was an issue. Eventually, a supplier was found and the goal for making a lightweight and yet functional fabric seemed possible.

In the end, a one-yard sample fabric for the work glove was made after using 200 yards of yarns for the client. Over the course of three years, many samples were made. The modification of fabric's texture or the stretch strength were done many times to ensure a high-quality cut resistant fabric is made professionally. Sometimes, flying to the U.S. to evaluate the test results at client's lab was needed. It was largely a matter of trial and error, expert consultation, and a lot of time and money devoted to the project. Three years later, Nam Liong had made it! A high-performance work glove fabric was created with Nam Liong's scientific curiosity and relentless efforts.

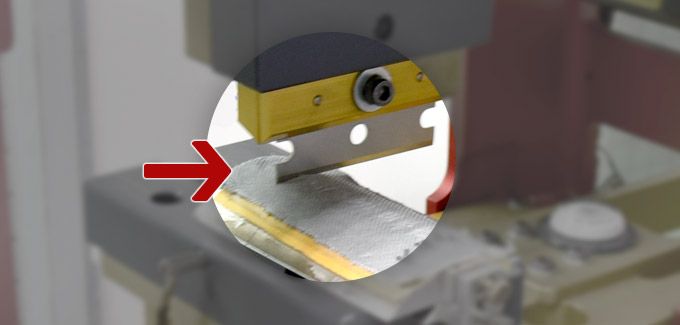

To pass international standards, Nam Liong owns cutting test equipment. The cutting test equipment allows Nam Liong's clients to receive fabric samples that have already passed the tests in Nam Liong's factory and are ready for other lab tests elsewhere. At the end of the day, the tricot is avoided due to Mechanix Wear's expertise on sewing. The 360-degree sewing technique is able to create a glove that feels so soft that the lining can be eliminated. Thus, money for material and labor is saved.

ANSI 9 cut & stab-resistant fabrics tested by cutting test equipment

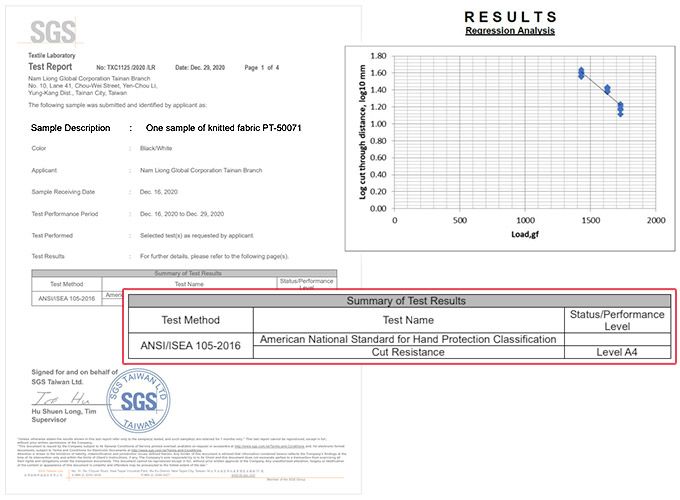

Hand Protection Fabric Sample ANS Test Results

"Respect For Lives, Care For The Environment" is Nam Liong's core value for the future, and therefore an ESG (environment, social justice, and governance) report was provided in 2022. BIO II™ - USDA certified bio-based rubber sponge wetsuit is a total solution for ocean lovers. ARMORTEX®, a series of technology and functionality enriched fabrics meeting EU RoHS and REACH compliance, has helped many clients to elevate their company's branding to a higher level. At Nam Liong, smart manufacturing is always considered to ensure win-win production.

Article sections

Based in Taiwan, Nam Liong Global Corporation is a technical fabric and bio rubber sponge manufacturer in the textile industry.

The provided effective technical fabric, Armortex®, is a breakthrough to many suppliers/retailers who wish to enhance their product functionality in the competitive market. Over the course of three years, many samples were made. The modification of fabric's texture or the stretch strength were done many times to ensure a high-quality cut resistant fabric is made professionally.

NAM LIONG has been offering world-class customers high-quality technical fabrics and bio rubber sponge since 1972, both with advanced technology and 50 years of experience, NAM LIONG ensures each customer's demands are met.