Tear Resistant, Anti-Abrasion, Lightweight Technical Kevlar® Fabric for A European Workwear Brand

Strong Kevlar® Fiber with Promising Performance for Your Workwear Fabric

Workwear Tear Resistance Woven Fabric Meets EU Regulations

Workwear Tear Resistance Woven Fabric Meets EU Regulations

ASMT D3886 Tear and Abrasion Resistance Functional Fabric | Armortex® Fabrics

For the last 15 years, Nam Liong has been providing durable technical fabrics to a 45-year-old prominent workwear brand from Sweden. The company offers professional craftsmen safety, protection, and efficient workwear for everyday lives. They have manufacturing factories located worldwide with 5,000 distributors in 15 countries. Nam Liong receives orders from their offices in Vietnam and Europe, specialized in providing reinforced kneepad fabrics. The high-quality tear resistant, anti-abrasion and lightweight technical Kevlar® braided fabrics have been purchased by the client for over a decade.

Five years ago, the client wished to create a new collection of workwear to correspond to today's fashion, hoping to also attract younger generations to wear them on a daily basis. In that case, the current fabric that they have been ordering wouldn't be suitable. Nam Liong had custom-made functional Kevlar® fabric samples available to the client to make a pair of work trousers that are abrasion resistant, feel comfortable and permit craftsmen to work with flexibility.

The anti-abrasion fabric provided by Nam Liong is a custom-made fabric that acts as a cushion for vulnerable parts, which is normally added to the outer layer of trousers or jackets. Synthetic lengthwise warped yarns can create high degree abrasion resistant fibers for shoulders, elbows, or knees, where added protection is required to prevent injury. Because Kevlar® can withstand the extreme temperature and at the same time also provide excellent strength, it is used to fabricate workwear fabric for the client. To extend the performance of the functional fabric, the yellow Kevlar® fiber is dyed black to assure its long-lasting appearance even with the constant rubbing during operations.

Nam Liong's functional Kevlar® filled fabric has passed ASMT D3886 tear and abrasion resistance tests.

Workwear, such as protective overalls, trousers, and jackets, must comply with EU regulations, which require products with CE marked in order to be sold in Europe. The client asked for the fabric to have high level of abrasion and tearing resistance. (i.e., abrasion-EN 530:2010 method 2, 12kPa, abradant- glasspaper grade F2, grit 100) The fabric must also pass ISO tear and tensile strength tests for coating and lamination. Nam Liong's functional Kevlar® filled fabric has passed ASMT D3886 tear and abrasion resistance tests, in addition to ISO tests.

Weaving is simply defined as the art of intertwining of threads. The fabric made with long strands has the characteristic of being firm, however, the hardness makes it difficult for craftsmen to move easily. Knitted Kevlar® fabric is the solution. The technical fabric would be resistant to wear and tear, stretchy, and flexible. The short fiber knitted fabric would meet EN 388: 2016 level 5 standards. Fabric anti-abrasion and water repellency treatments, including chemical coating, adhesion and dyeing treatments, will be conducted to maximize the performance. As a result, with the new selection of workwear trousers, the client’s sales went up. Since then, the procurement with the newly developed anti-abrasion fabric has increased by three times.

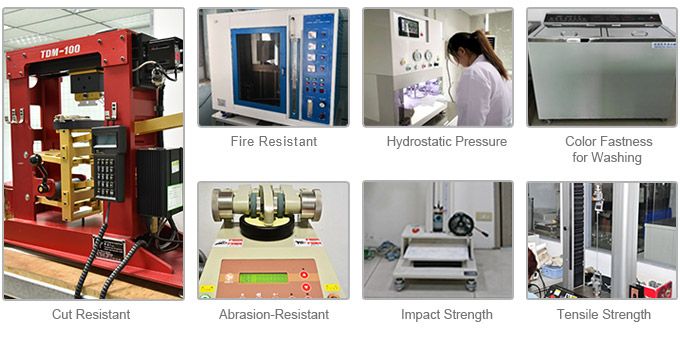

various tests are conducted to ensure the quality of fabric

Stockout or excess stock is never an issue due to the efficient inventory optimization in addition to the diversified supply chain in Taiwan. Nam Liong is a Kevlar®-focused fabric manufacturer with a great selection of specifications. Knitting and weaving of Kevlar® fibers at the plant allows them to have 100% inventory control of fabric. Likewise, the scale to create technical and functional fabrics for different applications is large. Regular clients’ material purchasing amount is always predicted and prepared in advance to assure on-time delivery. Semi-finished fabric is always stocked in a considerable amount to accommodate client's procurement anytime. Nam Liong’s fabric supply is agile and MOQ is negotiable.

"Respect For Lives, Care For The Environment" is Nam Liong's core value for the future, and therefore an ESG (environment, social justice, and governance) report was provided in 2022. BIO II™ - USDA certified bio-based rubber sponge wetsuit is a total solution for ocean lovers. ARMORTEX®, a series of technology and functionality enriched fabrics meeting EU RoHS and REACH compliance, has helped many clients to elevate their company's branding to a higher level. At Nam Liong, smart manufacturing is always considered to ensure win-win production.

Article sections

Based in Taiwan, Nam Liong Global Corporation is a technical fabric and bio rubber sponge manufacturer in the textile industry.

Synthetic lengthwise warped yarns can create high degree abrasion resistant fibers for shoulders, elbows, or knees, where added protection is required to prevent injury. Strong Kevlar® fiber with promising performance for your workwear fabric.

NAM LIONG has been offering world-class customers high-quality technical fabrics and bio rubber sponge since 1972, both with advanced technology and 50 years of experience, NAM LIONG ensures each customer's demands are met.