A Sustainable Textile Industry for A Brighter Future - ESG Report

OEKO-TEX®, bluesign®, GRS Certified Functional Fabric

Eco-Friendly Technical Fabric for World-Class Clients

Eco-Friendly Technical Fabric for World-Class Clients

It has been a tremendous change for a company that is constantly seeking improvement, both in the field of textile technology and the well-being of employees. First, ARMORTEX®, a series of technology and functionality enriched fabrics meeting EU RoHS and REACH compliance, has been developed, which are categorized into seven types: abrasion resistant fabric, cut resistant fabric, puncture resistant fabric, anti-slip fabric, stretchable fabric, reflective fabric, and flame retardant fabric. In 2016, to correspond with United Nation's 17 interlinked global goals (Agenda 2030) to a sustainable future, actionable steps were planned and executed. In 2022, An ESG report with the certification of AA1000 SES was delivered as a communication tool between Nam Liong and stakeholders, which permits stakeholders, including 287 suppliers, to evaluate Nam Liong based on the criteria of environment, social justice, and governance.

USDA Bio-Based Rubber Sponge Made With ECO Family Materials

As an eco-friendly fabric manufacturer, Nam Liong is taking actions to ensure the environmental impact of fabric production is monitored and controlled. For three years, the approach has been to create a highly effective and eco efficient textile production system, which reduces, reuses, recycles, and is renewable. Ultimately, Nam Liong will have a fundamental change with all the green strategies and earth-friendly methodology taking place. Fabric dyeing, finishing, and washing is one of the most polluting aspects of the textile industry, and Nam Liong has already invested a million USD into tackling air purification during the fabric manufacturing process, and it is scheduled to be completed in 2022. Wastewater treatment from fabric dyeing, finishing, and washing; and solar panel installation will also be addressed.

The implementation of ISO 14001 and ISO 13485 is to assure that the entire textile manufacturing process would take its ecological impact into account, such as carbon emissions and waste reduction, fossil fuel removal and so on. Suppliers of raw material and fabric aftertreatment would work closely to meet the regulatory compliance and standards, meaning fabric finishing, and physical and chemical processes will have the environment in mind. Nam Liong values all third-party assets/data and intellectual property, therefore, ISO 27001 was acquired in 2021.

Nam Liong is ISO 9001 Quality Management System & ISO 14001 Environmental Management System Certified

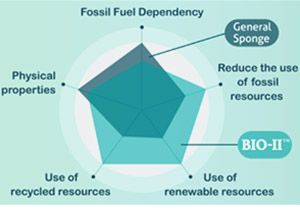

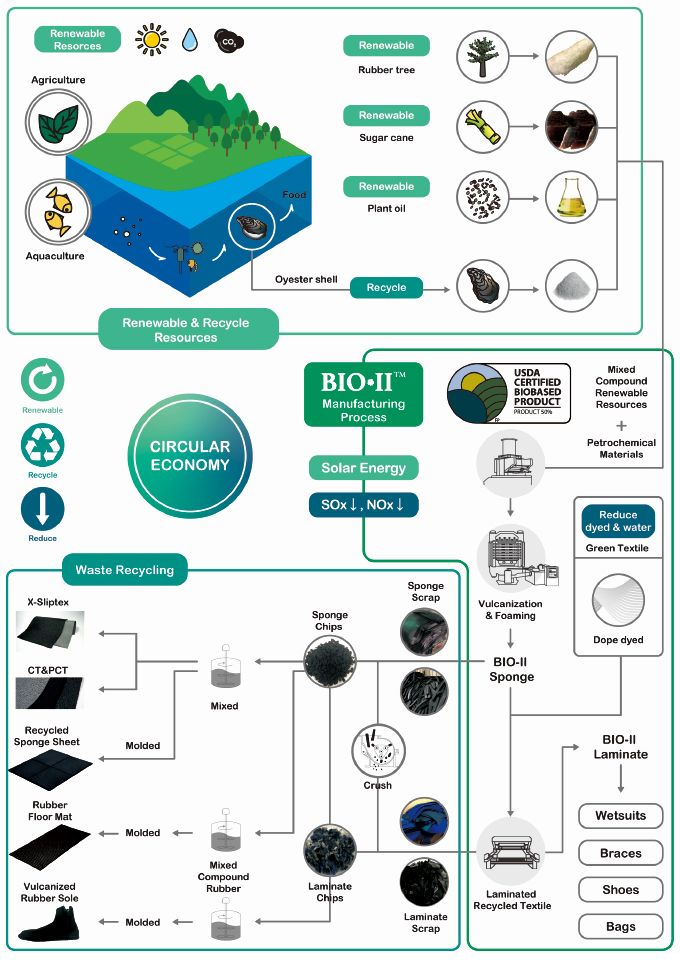

To replace synthetic neoprene, USDA bioPreferred oyster shell bio-based Bio II™ rubber sponge was developed by Nam Liong, with the FSC™(License Code : FSC™ C181797) certified rubber source. Vendors now can sell environmentally focused wetsuits to ocean and beach lovers with the selection from 30% to 90% bio-based rubber content.

In response to brands and their customer's desires for rubber sponge with sustainable attributes, seashell powder made bio-based rubber sponge was delivered, namely BIO II™.

The in-depth understanding of physical properties and chemical behavior to produce neoprene-free foam that is water-resistant with great heat retention and thermal insulation, and has good impact protection, is the advantage of Nam Liong's 50 years of neoprene experience. The sponge can be laminated with recycled fabric provided by Nam Liong to empower its functionality. Laminated rubber sponge material may or may not be fabric coated. Regarding the waste and pollution generated during production; Nam Liong has systemized the handling procedures to minimize the impact on the environment.

Textile Products From All Processing Stages Are Tested For Harmful Substances

The collaboration with World-class clients - NIKE, TIMBERLAND, RIP CURL, ADIDAS, SAMSONITE - is the drive for producing advanced functional fabrics. The obtaining of Oeko-Tex® Standard 100, bluesign® and Global Recycled Standard (GRS) certificates, in addition to the strict adherence to REACH, EU RoHS, ASMT D3886, CE, ANSI/ISEA standards, proves Nam Liong's ability to fabricate technical fabrics at the forefront of the industry.

Nam Liong has passed a number of international certifications

A circular economy is the solution to realizing eco-friendly textile production demands. Sharing, leasing, reusing, repairing, refurbishing, and recycling existing materials and products will be the core value along with fabric production. ISO 14064, the green gas emission management system, is applied to the fabric manufacturing process in accordance with TCFD (Task Force on Climate-related Financial Disclosures) standards, to mitigate the risks of climate change, as well as to be transparent about the ways in which the company is governed.

Circular Economy is a systems solution framework that tackles global challenges. As a textile manufacturer, Nam Liong has been implementing ISO systems and meeting international standards to protect our planet.

"Respect For Lives, Care For The Environment" is Nam Liong's core value for the future, and therefore an ESG (environment, social justice, and governance) report was provided in 2022. BIO II™ - USDA certified bio-based rubber sponge wetsuit is a total solution for ocean lovers. ARMORTEX®, a series of technology and functionality enriched fabrics meeting EU RoHS and REACH compliance, has helped many clients to elevate their company's branding to a higher level. At Nam Liong, smart manufacturing is always considered to ensure win-win production.

Article sections

Based in Taiwan, Nam Liong Global Corporation is a technical fabric and bio rubber sponge manufacturer in the textile industry.

In 2022, An ESG report with the certification of AA1000 SES was delivered as a communication tool between Nam Liong and stakeholders, which permits stakeholders, including 287 suppliers, to evaluate Nam Liong based on the criteria of environment, social justice, and governance.

NAM LIONG has been offering world-class customers high-quality technical fabrics and bio rubber sponge since 1972, both with advanced technology and 50 years of experience, NAM LIONG ensures each customer's demands are met.