ARMORTEX® - 7 Types of Technical Fabrics for Your Products with Outstanding Functionalities Requests

Protection for Stab, Spike, Fragments, Heat, Arc Flash - ARMORTEX®

DREF Friction Spinning System - Selective Fiber to Build Outstanding Fabrics

DREF Friction Spinning System - Selective Fiber to Build Outstanding Fabrics

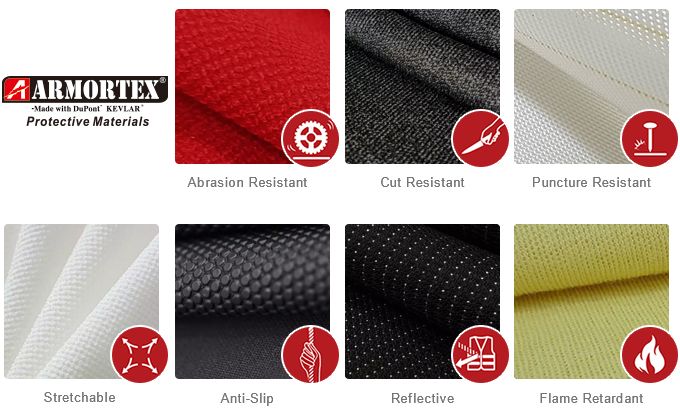

To satisfy market demand, a series of technical textiles, namely ARMORTEX®, has been developed by Nam Liong. ARMORTEX® is a set of seven technical-oriented textiles designed with enriched functionalities. There is abrasion resistant fabric, cut resistant fabric, puncture resistant fabric, anti-slip fabric, stretchable fabric, reflective fabric, and flame retardant fabric for you to choose from. The name of each fabric describes its high-performance functionality.

Nam Liong's multi-functional synthetic fabric, ARMORTEX®, can be applied to over 400 items, depending on the requirement of structure, performance, and functionality. Anti-stab, anti-slip or antimicrobial fabrics supplied with high-performance can be realized at Nam Liong. It is the 50 years of combined experience – the scientific mind and the in-depth understanding of fiber and fabric's physical structures, which permits them to fully execute the fabric manufacturing process.

7 Types of Technical And Functional Fabrics for Your Products

The scale of application is large; there are fabrics for lightweight running shoes, anti-abrasion boots, puncture-resistant gloves, water repellent bags, anti-tear motorcycle biker apparel, anti-stab & scuff gloves, workwear that prevents injuries, etc. Fabrics for stab, spike, fragments, heat, arc flash, you name it. ARMORTEX®, allows you to design products for both style and function. Nam Liong can also customize your fabric if it is beyond what they have.

The fast fabric sample delivery (7-10 days) and the flexibility to accommodate your product design is far greater than you can imagine. For first-time cooperation, the client and Nam Liong will each provide a test report for comparison. The fabric test report comprises weight, abrasion or piling, breathability, temperature, water repellency, stiffness, tear strength, or tensile properties. Any differences will be discussed and resolved, Nam Liong's RD team supports and advises with the knowledge of fabric. The goal is to meet international standards, whether the product is for the U.S. or European market. If you happen to be at a trade show such as the world leading fair A+A, you will see a fascinating range of forward-looking and state-of-the-art technical textiles represented by Nam Liong.

Compound wire mesh, fiberglass, nylon, rayon or polyester, can be wrapped around each other to fabricate fibers with diverse strengths.

Yarns such as Kevlar® are spun using this method. Multiple strands can be twisted together, or various tensions and thicknesses may be applied to yarns during spinning. Up to five mixed fibers, for example compound wire mesh, fiberglass, nylon, rayon or polyester, can wrapped around each other to fabricate fibers with diverse strengths. Within two decades, Nam Liong has transformed themselves into a protective fabric expert for manufacturers and retailers who request fabrics in a fast-paced consumer market as the fabric business has extended across industries.

Core Yarn Machine For High Performance Technical and Functional Fabrics

Nam Liong has been a Taiwan-based fabric manufacturer, with a focus on industrial fabrics, protective fabrics and technical fabrics for 50 years. Their competitive advantage is the yarns made by a specialized fiber spinning/weaving machine and the ability to create fibers with various tensile strength using a mixture of fibers, and over 40 patented textile/fabric products. To do so, knowledge of every synthetic fiber's physical property is essential.

Another advantage is the years of fabric finishing and treatment experience. Fabric aftertreatments, including coating, laminating, chemical dipping, emerging, dyeing, different bio-macromolecules imparted to textiles and so forth, are fabric function adding operations. Function-enforced fabric requires processes, for example anti-abrasion and fire-retardant fabric needs more processes like lamination between fabric, neoprene and TPU. Leather lamination and coating can enrich the functionality of anti-cutting fabric.

Fire retardant fabrics KAG-12168FS with EN-11612-FR certificate

Fabric Inspection - functional fabric quality inspection process

Cost is an important criterion of textile, which can be managed in Taiwan thanks to its geographic advantages and the amazing supplier network across all industries. The vertically integrated textiles production is planned from start to finish with fiber preparation, all the way through weaving or spinning, and the aftertreatment of fabric. Clients have chosen Nam Liong as a textile manufacturer due to the smooth supply chain. The fifty-year long evolution of Nam Liong's supply chain has turned them into a proficient textile provider.

In the supply chain, vendors can be reached when special tungsten wire meshes, or sustainable resources are requested to fabricate an eco-friendly and anti-abrasion fabric. Aftertreatment services are available to create functional fabrics according to the application; wastewater handling and recycling, environmentally friendly adhesive and chemical, the comprehensive supply network can result in low-cost regional fabric manufacturing.

From medical textiles, technical textiles, and military textiles, high-performance is essential. To further understand the design of fabric, (i.e., scientific, and physical property) Nam Liong has been inviting prominent professors and senior consultants in the textile field to learn from them. Their know-how has helped to accumulate knowledge on the future technology of fabric; and listening to their advice has allowed Nam Liong to identify their strength in the market.

Complete Vertically Integrated Supply Chain In Taiwan– Your Fabric Is Competitive In All Aspects

To improve the competitiveness in the functional fabric sector, Nam Liong provides virtual learning instructions.

Over time, the textile area has changed and evolved, Nam Liong has always remained flexible and improved along with the need to deliver current fabric solutions to clients. Today, the structure of fiber is more complex, smarter, and greener. In 2022, Nam Liong will continue to be creative on the development of fiber and collaborate with other industries to generate high-quality fabrics to incorporate client's stunning designs. The collaboration with a top-ranking textile university in Taiwan is one of the approaches, the school provides fabric test labs and processing equipment to cultivate innovative talents. Cross-training, internship, manufacturing plant visitation, work placement, resource sharing, attending international conferences and government funding applications are implemented, all of these are to tackle the challenge in fiber science in hopes of a new textile technology in the future.

Collaboration with top-ranking textile universities in Taiwan to cultivate innovative talents.

"Respect For Lives, Care For The Environment" is Nam Liong's core value for the future, and therefore an ESG (environment, social justice, and governance) report was provided in 2022. BIO II™ - USDA certified bio-based rubber sponge wetsuit is a total solution for ocean lovers. ARMORTEX®, a series of technology and functionality enriched fabrics meeting EU RoHS and REACH compliance, has helped many clients to elevate their company's branding to a higher level. At Nam Liong, smart manufacturing is always considered to ensure win-win production.

Article sections

Based in Taiwan, Nam Liong Global Corporation is a technical fabric and bio rubber sponge manufacturer in the textile industry.

ARMORTEX® is a set of seven technical-oriented textiles designed with enriched functionalities. There is abrasion resistant fabric, cut resistant fabric, puncture resistant fabric, anti-slip fabric, stretchable fabric, reflective fabric, and flame retardant fabric for you to choose from. The name of each fabric describes its high-performance functionality.

NAM LIONG has been offering world-class customers high-quality technical fabrics and bio rubber sponge since 1972, both with advanced technology and 50 years of experience, NAM LIONG ensures each customer's demands are met.