Water Repellency Technique on Neoprene Sheet for Your Luxury Bag Market

More Than Just a Neoprene Fabric Supplier

In-Depth Understanding of Fabric & Rubber Sponge's Characteristic and Property

In-Depth Understanding of Fabric & Rubber Sponge's Characteristic and Property

Neoprene Sheep With Perforated Holes For a Bag Company

Nam Liong's neoprene sheet is used by a luxury bag brand from Australia. They sell bags with beauty and simplicity in their creations. Tote and bell bags with perforated holes are an iconic look, and two thirds of their customers are from the high-end market in Japan. The overwhelming number of counterfeits in the market tells the popularity of the bag. Over the course of the last six years, orders increased significantly. The client's bag took over the market in Asia, and Nam Liong continues to supply high-quality neoprene fabrics.

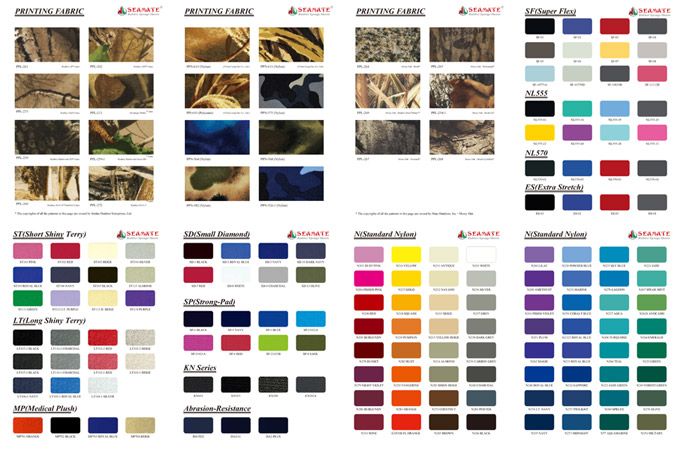

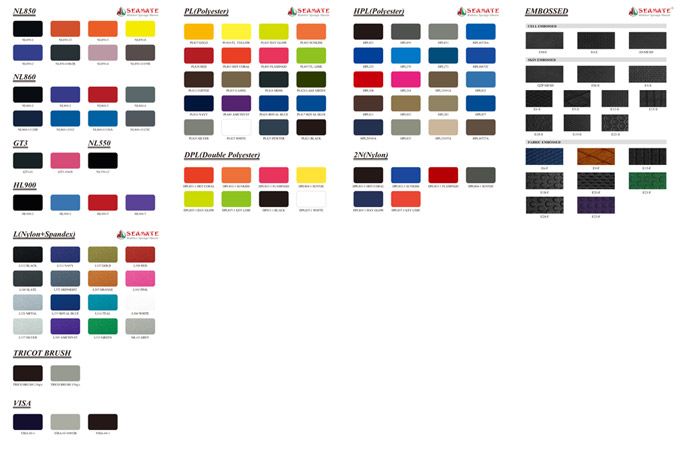

The fabric for bags was requested to be neoprene, with a high level of dirt and water protection, washable, fast-drying, conforming to REACH, RoHS and CPSIA standards, and to be PVC free. Thickness, firmness, straightness and loading capacity needed to be precise. No sagging, each bag must have 25 degrees of firmness, assured with ASKER Type C test. And the surface of the fabric should not have a single stain. Considering all the requests, a custom-made neoprene fabric was developed with all these qualities. During the sampling period, 100 to 200 colors of fabrics were provided to go with the black neoprene sheet to create the finest colors for the tote bags. To cope with the fast-paced handbag fashion trends, 7-10 days sample delivery was provided.

Nam Liong provides 100-200 colors of fabrics to go with neoprene sheets to create the finest colors for your product.

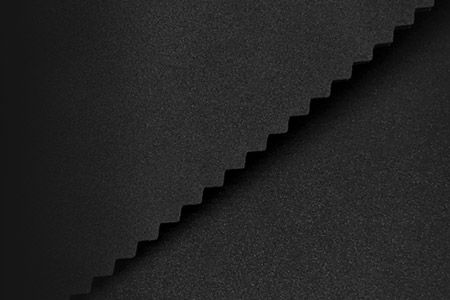

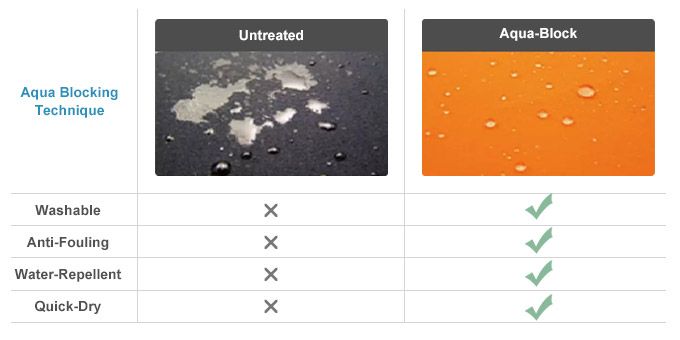

Nam Liong has developed a water repellency technique to address the contradiction between having a neoprene fabric that is water repellent and has great adhesive bonding. Water repellency technique is designed for a neoprene fabric to receive the desired adhesive effect, and water-resistant to block oil and dust simultaneously.

After water repellency technique is applied, AATCC22 water repellency spray test shows that neoprene fabric remains 70% waterproof.

Neoprene Fabric with Water Repellency Technique

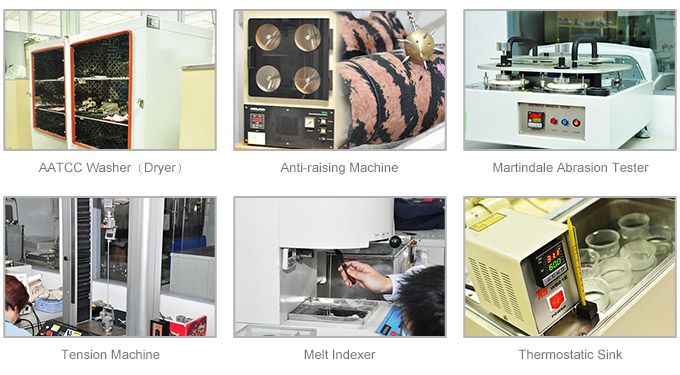

Before a high-quality neoprene fabric is delivered to a client, there's a series of processes that need to be done. Onsite and offsite inspections take place routinely, neoprene fabric's property adjustment is made for certain functions, machine roller cleaning is completed to make sure there's no oil or grease on the fabric, thickness and firmness are examined before and after perforation is conducted on the neoprene fabric, fabric's surface is clean, and so forth. There's a set of standards to comply with, and if an issue occurs, the clients is immediately informed to ensure that they always receive the most updated status. Nam Liong pays attention to the details, and corrections are constantly made to ensure the objective is achieved within the schedule.

Inspections take place routinely, neoprene fabric's property adjustment is made to meet international standards.

Nam Liong's Flexibility on Color Selections

In recent years, Nam Liong has transformed themselves and become fashion companies' favorite by providing functional and technical fabrics. The development of fabric technology and functionality to create stylish products and yet still meet international eco-friendly manufacturing standards is challenging, however necessary. In the fast-paced fashion industry, items are put in stores seasonally with selections of shapes and colors. Nam Liong's flexibility on color selections and outstanding fabric performance has allowed clients to stay competitive.

Supplying neoprene fabric that can make a bag stand takes a broad study of the rubber sponge and the fabric. The fabric's characteristics and properties, including those that can change the performance, need to be considered. Nam Liong doesn't just say "Yes, we can do it." Every time a client shows up with a request, Nam Liong would evaluate the feasibility and communicate with the client along the way.

Combining Two Rubber Polymers in One Operation For a Footwear Brand

Nam Liong didn't produce neoprene fabric for a bag that would dominate the market in one day, just like when a waterproof boots and footwear brand reached out to them and asked them to make boots that combine rubber and neoprene in one operation. Each boot has 30% scuba grade neoprene, 70% rubber, and offers 100% waterproof protection, natural insulation, and flexibility in the muddy or snowy conditions. The complexity of production made Nam Liong struggle, but it didn't stop them. Stabilizing the material under high pressure and high temperature can be difficult, but Nam Liong's know-how and relentless efforts made it happen. Today, 150,000 pairs of boots per month during winter season until spring are delivered regularly from Nam Liong to this boot company.

Nam Liong helps your product to obtain certifications, such as UL, Oeko-Tex 100, USDA, as well as supplies eco-friendly, 100% neoprene-free rubber sponge, for products that are focused on environmentally friendly buyers. Clients can go green but still have options to create functional products by providing biobased rubber sponges with different percentages of biomaterial. As a GRS certified supplier, Nam Liong can also help you to set up recycling systems. Factory tours are accessible to have an in-depth understanding of each manufacturing process. Transparency is the key; all questions will be answered at Nam Liong.

"Respect For Lives, Care For The Environment" is Nam Liong's core value for the future, and therefore an ESG (environment, social justice, and governance) report was provided in 2022. BIO II™ - USDA certified bio-based rubber sponge wetsuit is a total solution for ocean lovers. ARMORTEX®, a series of technology and functionality enriched fabrics meeting EU RoHS and REACH compliance, has helped many clients to elevate their company's branding to a higher level. At Nam Liong, smart manufacturing is always considered to ensure win-win production.

Article sections

Based in Taiwan, Nam Liong Global Corporation is a technical fabric and bio rubber sponge manufacturer in the textile industry.

The bio rubber sponge supplied by NAM LIONG has no sagging, each bag must have 25 degrees of firmness, assured with ASKER Type C test. And the surface of the fabric should not have a single stain. AATCC22 water repellency spray test shows that neoprene fabric remains 70% waterproof.

NAM LIONG has been offering world-class customers high-quality technical fabrics and bio rubber sponge since 1972, both with advanced technology and 50 years of experience, NAM LIONG ensures each customer's demands are met.